NEMA Wiring Schematic Guide for Electrical Specialists

Approximately 70% of electrical failures across installations result from inadequate wiring techniques. These figures underlines the need of complying with recognized guidelines, highlighting NEMA wiring diagrams’ significance for electrical experts. Via these diagrams, wiring arrangements that fulfill both performance effectiveness and optimal security standards are delineated.

The objective of this guide is to equip electrical professionals with comprehensive knowledge into NEMA norms. Highlighting the value of proper electrical installations is essential. By learning these rules, technicians can significantly minimize the risk of accidents and confirm they adhere to safety standards backed by Installation Parts Supply. Knowledge in l 14-30 plug is vital whether designing modern setups or servicing current ones, as it enhances the ability to provide reliable and dependable electrical systems.

Salient Features

- NEMA wiring diagrams are essential for ensuring electrical protection and conformity.

- Correct wiring methods can decrease electrical malfunctions considerably.

- Comprehending NEMA criteria enhances the efficiency of electrical installations.

- Installation Parts Supply supports compliance with regulatory standards in electrical work.

- NEMA schematics accommodate a variety of uses across multiple fields.

Understanding NEMA Criteria and Why They Matter

NEMA standards are pivotal in the electrical field, steering security and functionality meticulously. Formulated by the National Electrical Manufacturers Association, they set key criteria for designing, examining, and labeling electrical gear. It ensures consistency and reliability across all electrical configurations, which is of great value.

Identify the NEMA Norms?

NEMA designations span from levels 1 to 13. Each level defines the parameters necessary for electrical appliances to function effectively. For example, NEMA 1 delivers fundamental indoor protection but does not offer dust resistance. Conversely, NEMA 4 secures devices is watertight, a must for withstanding considerable water immersion. Comprehending these classifications is crucial in choosing appropriate equipment.

Why NEMA Standards Matter for Electrical Protection

The function of NEMA criteria in maintaining electrical safety is substantial. They contribute greatly in minimizing shock risks, equipment failures, and fire dangers. Correct adherence to NEMA ratings enables devices to perform safely under particular ambient conditions. For external usage, NEMA 3 ratings provide protection against the elements, shielding the device from inclement conditions like precipitation and snow. In areas at risk of explosions, classifications such as NEMA 7, 8, and 9 are critical for upholding security.

Implementations of NEMA Standards in Wiring Schematics

The use of NEMA criteria in wiring schematics is vital for protected, effective electrical installations. These drawings utilize standardized symbols and structures based on NEMA ratings, simplifying the understanding of detailed electrical setups. This standardizing is helpful. It encourages transparency, consistency, and minimizes misinterpretations, and thereby boosting electrical protection across domestic and factory environments.

NEMA Wiring Schematic Fundamentals

NEMA wiring schematics are essential for electrical professionals, making intricate junctions transparent. They detail the linkages and components in different setups. By understanding the parts, kinds, and symbols of NEMA diagrams, professionals can boost their operations in setups and servicing.

Elements of NEMA Wiring Schematics

NEMA diagrams include key parts for specific electrical installations. You’ll discover wiring connection points, couplers, and other hardware for secure linkages. Every piece guarantees energy is spread optimally, in accordance with safety protocols.

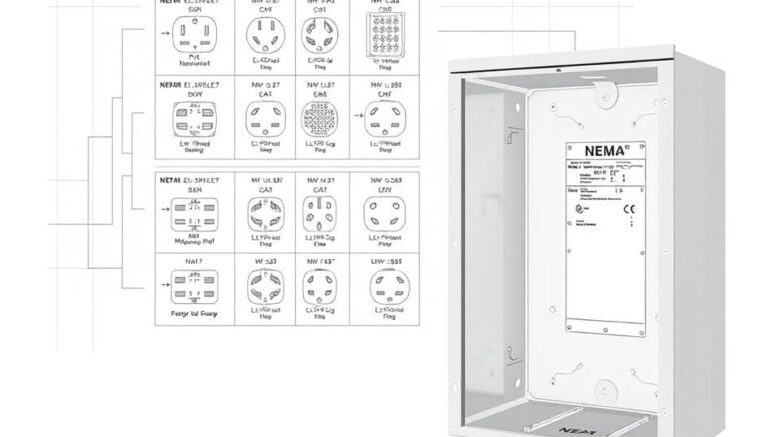

Varieties of NEMA Wiring Diagrams

NEMA employs different schematics, like connection blueprints and electrical layouts. Such diagrams depict equipment relationships, while designs illustrate energy distribution. Opting for the correct drawing helps with problem solving and installation.

Frequent Symbols Employed in NEMA Wiring Diagrams

Icons in wiring drawings are crucial for clear clarity. They depict switches, circuits, and couplers. Knowing these icons assists crews interpret diagrams correctly. Such practice ensures setups comply with NEMA criteria.

NEMA Wiring Schematic Attributes

For electrical specialists, understanding the key aspects of precise electrical wiring schematics is crucial. These drawings bring both clarity and completeness, synchronizing installations with NEMA criteria. They necessitate precise marking and sizing to minimize installation errors. Such practices promote a protected and highly efficient working environment.

Essential Attributes of Accurate Electrical Wiring Schematics

Precise electrical wiring drawings are essential in electrical projects. They embody crucial attributes such as:

- Lucidity: Schematics must be simple, lowering errors in understanding.

- Wholeness: They must include all vital components, linkages, and electrical ratings.

- Adherence to Standards: Complying with NEMA criteria is mandatory for securing security and functionality.

- Thorough Annotation: Unambiguous markings on each part are crucial for grasping and minimizing errors.

- Correct Scaling: The proportions should replicate the actual setup to portray the configuration accurately.

Comprehending NEMA Coupler Pinout

The insight into NEMA coupler layout is vital for establishing proper junctions in electrical networks. Knowledge about particular pin configurations ensures security and appliance functionality. There is a diversity of NEMA interfaces, crafted for specific voltage levels and amperages, covering:

| Connector Model | Current Rating | Voltage Rating |

|---|---|---|

| L5-15 | 15A | 125V |

| L5-20 | 20A | 125V |

| L14-20 | 20A | 125/250V |

| L1430C | 30A | 125/250V |

| L620C | 20A | 250V |

| L1430C | 30A | 125/250V |

| L630R | 30A | 250V |

Grasping NEMA connector layouts is vital for reliable linkages, enhancing effectiveness. It’s paramount to pair interfaces with devices correctly using rotary-lock or straight blade variants, to prevent dangers.

NEMA Appliance Wiring

NEMA appliance wiring includes diverse arrangements for safe electrical appliance interfaces. These guidelines guarantee that appliances work together reliably, reducing risk. Knowing the various NEMA equipment and their wiring is essential for technicians.

Various Types of NEMA Units

NEMA classifies appliances by category based on voltage and flow demands. Primary configurations are:

- 2-Pole 2-Wire

- 2-Pole 3-Wire Grounding

- 3-Pole, 3-Wire

- 3-Pole 4-Wire Grounding

- 4-Pole, 4-Wire

- 4-Pole 5-Wire Grounding

These setups are utilized in homes and manufacturing plants, supporting 125V, 208V, and 480V.

NEMA Plug Wiring Demystified

NEMA plug wiring differs to meet various electrical demands, with twist-lock types ensuring reliable junctions in shaky conditions. For instance, the L5-15 plug operates at 15 amperes, frequently used in business sites, whereas the L14-20 is intended for 20 A at 125/250 voltage.

The NEMA designation system assists in selecting the right plugs, emphasizing features like electrical polarity and earthing. This meticulousness secures that appliances perform reliably.

NEMA Receptacle Wiring Instructions

Accurate wiring of NEMA receptacles conforms to electrical codes and safety guidelines. Such as, L530R receptacles should be wired for 30 amperes at 125 V, with L630R models for 250 voltage. Correct grounding is crucial to dodge electrical accidents.

Choosing accredited NEMA plugs and sockets secures safe, regulation-compliant configurations. It’s critical to refer to official protocols when setting up.

NEMA Motor Wiring and Applications

NEMA motor wiring is essential in electrical design, especially for industrial use. Knowing how NEMA motor setup works secures that machines are set up for best efficiency. Such devices, like single-phase and three-phase types, need proper wiring to function reliably and efficiently.

Overview of NEMA Motor Wiring

Grasping NEMA motor wiring requires familiarity of linkages and configurations. Most three-phase motors offer dual-voltage, signifying they can run on both low (208-230V) and high power levels (460V). Wiring at high voltage results in lower current draw than at low voltage. High voltage perks include smaller wires for the supply, a major benefit for units over 10 HP.

While both NEMA and IEC appliances are utilized in the market, NEMA models are usually larger and more expensive than IEC ones for under 100 HP uses. NEMA trips vary from size 00 to 9, suitable for various functions. A typical attribute in NEMA controllers is a Fault Class of 20, designed to trip when a motor’s current exceeds six times the Full Load Amperage in 10 seconds.

Opting for the Correct NEMA Motor Configuration

Opting for the correct NEMA motor configuration influences system performance and safety. A standard three-wire control circuit uses three wires for a start/stop pushbutton panel, allowing direct motor management. Common three-phase arrangements include the 12 Lead Dual Voltage and 6 Lead, facilitating Wye and Delta arrangements.

IEC motor starters frequently incorporate phase monitoring, enhancing safety. They also feature adjustable Trip Classes for tailored protection in low voltage levels operations. Furthermore, many units have thermal protection, vital for Single Phase and Dual Voltage setups.

| Arrangement | Voltage Type | Amperage | Usual Function |

|---|---|---|---|

| 12 Lead Dual Voltage | Dual Voltage (208-230V / 460V) | Motor size dependent | Applications with Wye Start and Delta Run |

| 6 Lead | Single or Dual Voltage | Maximum 32A | Wye or Delta connections |

| Single Phase | One Voltage | Dependent on adjustment (1-5A) | Applications with Two Speed, Two Winding |

| Delta Connection | High-Power Voltage | Depending on setup | Current Transformers, multiple configurations |

As a Final Point

Understanding NEMA wiring diagrams and norms is essential for electrical professionals seeking to boost their expertise and comply with electrical safety standards. These principles guarantee safe and effective electrical installations but also prevent risks linked to incorrect wiring. As mentioned, following NEMA norms yields the enhanced performance of diverse NEMA appliances and configurations.

For electricians, the availability of high-quality supplies can greatly affect the result of their projects. Installation Parts Supply presents a extensive range of wiring products in accordance with NEMA standards. This enables specialists to obtain essential elements for fulfilling these significant standards. Superior supplies and profound expertise of NEMA wiring diagrams substantially improve installation safety and performance.

In your journey through electrical setups, always put safety and accuracy first. Gaining expertise in NEMA criteria offers the knowledge needed for implementing best practices correctly. This guarantees that each electrical link made meets superior criteria.

Frequently Asked Questions

Which are NEMA wiring schematics?

NEMA wiring schematics showcase the arrangements and linkages of NEMA-standard electrical devices. They comply with safety and operational norms set by the National Electrical Manufacturers Association.

Why are NEMA norms important for electrical safety?

NEMA criteria are key to setting safety and performance benchmarks for electrical gear. These guidelines help electrical specialists reduce electric shock, equipment failure, and fire risk.

Which elements are crucial in a NEMA wiring diagram?

Essential components in a NEMA wiring diagram consist of electrical layouts and junction blueprints. These schematics also include thorough annotations and illustrate the electrical system’s various parts precisely for installations.

Which kinds of NEMA wiring schematics are used?

Multiple NEMA wiring schematics serve various needs, including energy distribution layouts and interconnection diagrams for components. Each layout fulfills a specific role in electrical systems.

What are common symbols employed in NEMA wiring diagrams?

Common symbols in these diagrams represent switches, interruptors, receptacles, and additional components. Employing these symbols facilitates clear interaction and accurate analysis of wiring schematics.

Which are the main features of accurate electrical wiring drawings?

Precision in electrical wiring schematics is defined by their lucidity, comprehensiveness, and detailed labeling. They must align with NEMA standards to prevent mistakes in installation.

Define a NEMA connector layout?

A NEMA connector layout depicts electrical junctions at a connector, showing specific pin assignments. This ensures safe and optimal linkages in electrical networks.

What are the different types of NEMA devices?

NEMA appliances include various electrical sockets and connectors, like connectors and outlets. They are engineered for various ampere and power criteria to fulfill particular operational demands.

In what way is NEMA plug wiring set up?

NEMA plug wiring depends on specific ampere and power needs, following safety guidelines and code compliance for various electrical applications.

Which standards are there for NEMA receptacle wiring?

Recommendations for installing NEMA outlets underline complying with electrical standards, securing proper charge alignment, and selecting appropriate cable sizes. This ensures both security and functionality in electrical setups.

Describe how to wire a NEMA motor efficiently?

To wire a NEMA motor, one must grasp its particular one-phase or three-phase configuration. Opting for the correct wiring method is essential, along with practicing electrical security for optimized motor performance.

Which factors should be considered when selecting a NEMA motor configuration?

Selecting a NEMA motor arrangement requires an evaluation of the system’s voltage and current demands and operational characteristics. It’s also crucial to verify compatibility with current systems for reliable performance and security.